Getting manufacturers to return to the U.S. without hurting consumers or the overall economy is about cost. We need to reduce the cost of manufacturing in the U.S. Most of you will scoff at this idea, but it is within our ability to lower our total cost of manufacturing to be globally competitive while at the same time increasing real pay for the poor and middle class. To achieve this vision, we need to successfully innovate across our economy to boost productivity, increase the demand for our workers and improve labor market efficiency.

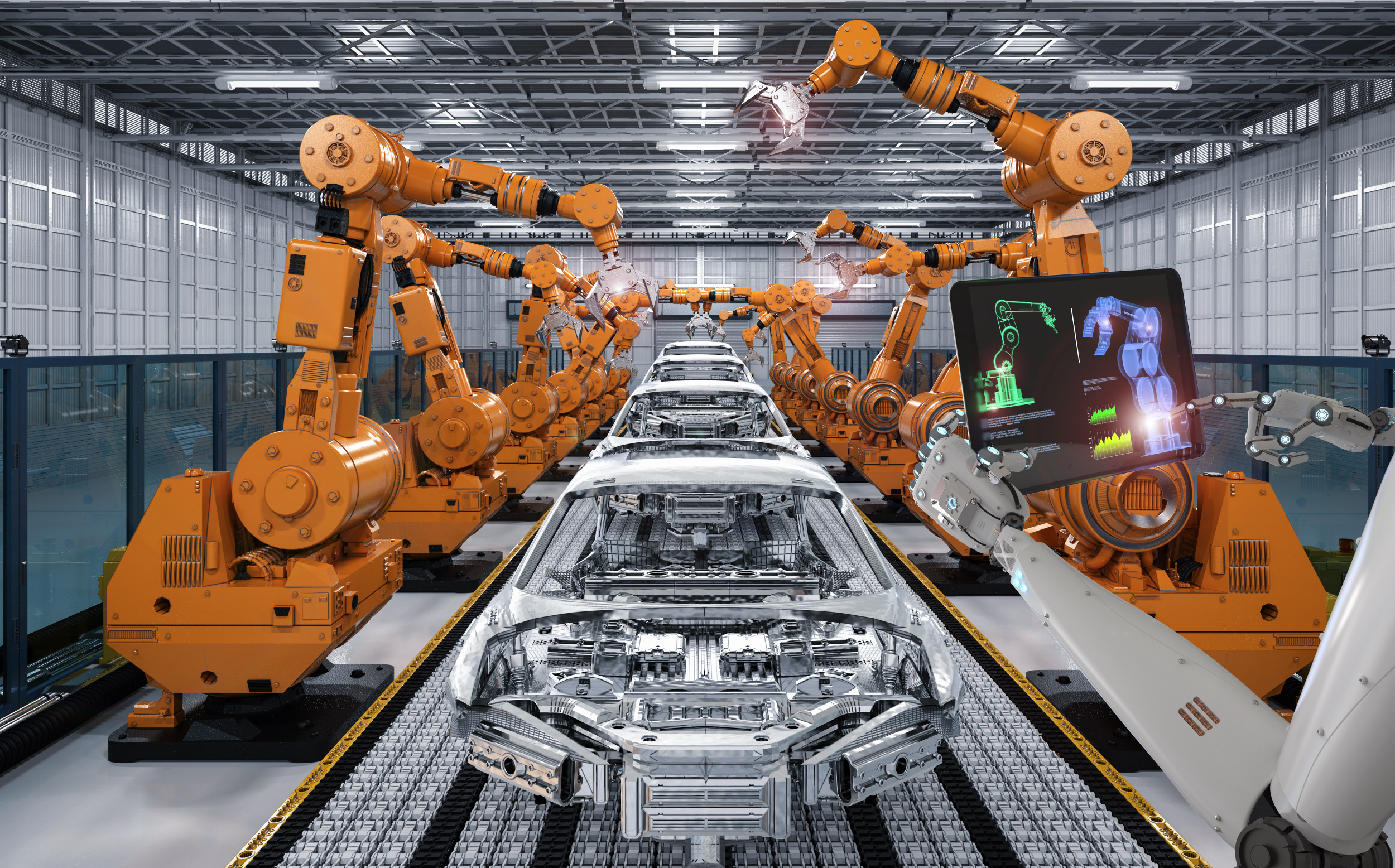

First, manufacturing costs in China are generally $95 to $97 per $100 in the U.S. as of 2019 according to BCG. This difference is probably a lot less than what most of you thought it was. These are averages for selected regions of each nation, so it depends on several factors to determine if an individual product is cheaper to make in China or if making it in the U.S. is an option. The more automated the manufacturing, the more worker skills that are required to manufacture the product or the more energy intensive the manufacturing is, the more likely it can be cost effectively manufactured in the U.S. China and other low-cost geographies have the advantage when manufacturing requires large numbers of low-cost workers to manufacture with no suitable cost-effective automation alternative. The total cost of manufacturing changes over time and has recently been most effected by the productivity of workers, energy costs and currency valuations.

Second, our manufacturers and other businesses seem to be good at technological innovation but are not as good at management innovation. Business management repeatedly tries to reorganize, reduce staffing, etc. in an attempt to increase productivity and save money. However, the research shows they fail more often than they succeed. Many of these “improvement” efforts result in loses after just a few years because new employees need to be hired and trained to fill the gaps in customer satisfaction that were caused by the previous reorganization, staff reduction or other improvement attempt. No long-term productivity improvements or cost savings are achieved through most of these efforts.

Finally, our politicians have not served the people’s interests or even business’ interests for decades. They have served their own interests which has created extremely complex and costly tax, healthcare, education, retirement, social support and work benefit systems. The tax system alone adds as much as 7.5% of GDP in compliance and efficiency costs to our economy. If we include the bloated costs of healthcare as a side effect of the tax system, we could add as much as another 9% of GDP in compliance and efficiency costs to that total. The more we dig into the true costs of these systems, the more we realize there are huge opportunities for productivity improvements that would result in cost reductions for manufacturers and real pay increases for everyday Americans.

The news is not all bad. There are simple solutions to boost productivity by lowering these systems cost while increasing real pay both in the short and long terms. There are two major challenges we need to address simultaneously. First, we need to replace our existing tax, healthcare insurance, college funding, retirement, social support and work benefit systems with a tax on business sales and services to the public, contributions to our own flexible savings accounts and three refunds to lower manufacturing costs by removing most of the direct and indirect costs of taxation and the compliance and efficiency costs of work benefits from their products. These cost reductions will boost productivity and make the U.S. the largest low-cost manufacturer in the world. Labor market efficiency will also improve due to the portability of work benefits achieved by funding them through the workers’ own flexible savings accounts instead of through their employer. This in turn will increase demand for workers and their pay. Second, we need to focus our education system on teaching students how to innovate and use technology to increase productivity of workers and improve the decision making of business leaders and managers. This will put us on a path to long term, sustainable, increases to worker productivity and the real wage increase that come with that.